Reliable HMI Solutions for Food & Beverage Manufacturing

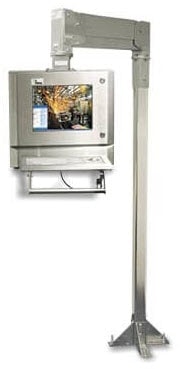

In today’s highly automated food and beverage production environments, managing complex processes requires precision, reliability, and real-time control. That’s why production supervisors depend on rugged industrial human-machine interface (HMI) systems. Positioned close to processing lines on the factory floor, these HMIs allow operators to monitor performance, troubleshoot equipment, and optimize operations—all in real time.

Modern industrial HMIs offer advanced hardware capabilities, flexible software integration, and comprehensive device management, making them essential tools for ensuring efficiency, safety, and compliance in demanding production settings.

Sanitation is a top priority in food processing plants. Daily cleaning protocols—mandated by federal regulations—require all equipment to be washed down with high-pressure, high-temperature water and harsh chemical-based sanitizers. To meet these requirements, food and beverage manufacturers invest in rugged HMIs specifically designed to withstand intensive washdown procedures.

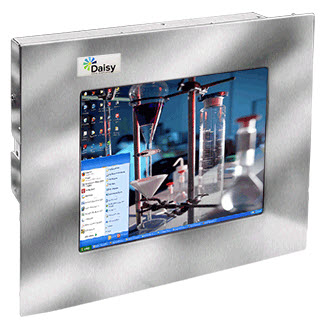

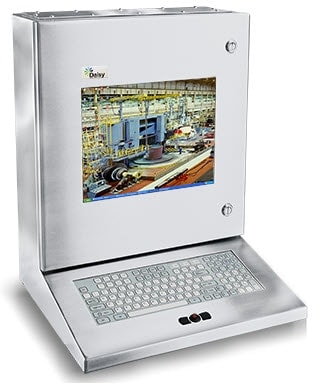

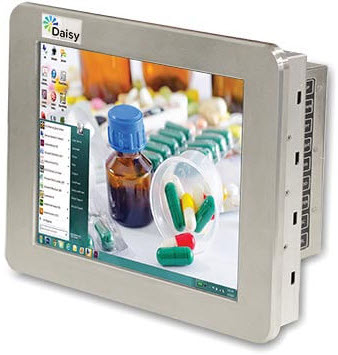

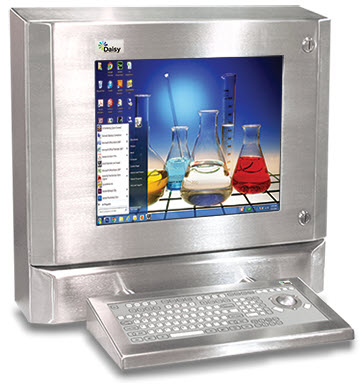

Daisy Data Displays provides HMI systems built for this environment. Our units feature fully sealed enclosures, corrosion-resistant stainless steel, and hygienic designs that ensure long-term performance under constant exposure to moisture, heat, and cleaning agents.

Food & Beverage Products

Critical features to look for in industrial HMI’s for food & beverage applications.

Recommended Products

The following Daisy Data Displays products are frequently used in wide array of Food & Beverage applications. Click learn more to view our available catalog of solutions.

Model 2123AB

2445 Series

2570 Series

2573DB Series

2150AA Series

2620/2520KP Series

2720/2720KB Series

2750/2750KB Series

2610/2510KP Series

2660/2560KP Series

4150AA Series

4320/4520KP Series

4570AB Series

4720/4720KB Series

4750/4750KB Series

4310/4510KP Series

4360/4560KP Series

6800 Series

6900 Series

6950 Series

OEM Series

9040-9050 Series

Model # 9016

Model # 9017

Model # 9123AK

Model # 9167

Model # 9173

Applications of Food & Beverage Products

Industrial HMIs play a crucial role in various aspects of the Food & Beverage industry, contributing to efficiency, safety, exploration, extraction, and overall operations. Here are some key applications where computers are used in the Food & Beverage industry:

Choose the Right Food and Beverage HMI Solution

Well-designed HMIs have become an essential tool for monitoring and controlling highly complex and sensitive operations in today’s food and beverage production facilities. At Daisy Data Displays, we work with clients in the food and beverage industry to design and configure HMI systems for a wide range of equipment and processes. When you partner with us, you can expect:

-

Custom solutions. From glove-friendly touch screens to fully sealed, stainless steel enclosures built for washdown environments, our HMIs are tailored to meet the rigorous hygiene and operational needs of the food and beverage industry. We support both high-volume OEM requirements and specialized, small-scale applications.

-

Regulatory compliance. Our HMIs are designed to help facilities comply with FDA, USDA, and HACCP standards, offering NEMA 4X and IP66-rated enclosures that withstand frequent high-pressure washdowns and prevent contamination risks. For added convenience, our products can be sorted by rating and ISO certification to match specific compliance requirements.

-

Turnkey integrated solutions. Daisy HMIs can be deployed as standalone systems or seamlessly integrated into existing process control architectures, streamlining operations while supporting regulatory traceability and documentation.

-

American-made products. Manufactured in the USA, our solutions deliver exceptional quality, faster lead times, and responsive customer support throughout the production lifecycle.

-

Lifetime product support and upgrades. We provide lifetime support and regular technology upgrades, ensuring systems remain reliable, efficient, and compliant with evolving food safety standards.

To learn more about our HMIs and how they can be configured to fit your life science application, please contact us today or request a quote.

Processing

Packaging

Quality Assurance & Sanitation

Optimized for Plant Floor Control

Industrial HMIs are critical for controlling and monitoring automated equipment across processing lines. Installed directly on the factory floor, our systems help supervisors:

• Monitor real-time performance

• Troubleshoot issues quickly

• Optimize efficiency and uptime

All with intuitive interfaces and robust device management tools.

Engineered for Sanitation & Washdown

Food and beverage facilities require daily washdowns using high-pressure, high-temperature water and harsh cleaning agents. Our HMIs are:

• Fully sealed and corrosion-resistant

• Built with stainless steel enclosures and beveled edges

• Rated up to IP66 and IP69K for dustproof and waterproof protection

These features ensure compliance with FDA, USDA, and other federal sanitation standards.

Clean-in-Place (CIP) Ready

Industries using CIP systems—such as dairy, beverage, brewing, corn wet milling, processed foods, and cosmetics—depend on rugged HMIs that can:

• Withstand daily chemical exposure

• Operate through intense cleaning cycles

• Maintain long-term reliability without corrosion or damage

Seamless PLC & System Integration

Food and beverage production relies on diverse control systems to manage complex processes. Daisy Data Displays’ industrial PCs and HMIs are designed to integrate seamlessly with:

• Leading PLC platforms, including Rockwell Automation, Siemens, and Aveva

• Advanced process control systems such as Emerson DeltaV™

• Cloud-based PLC solutions for remote monitoring, virtualization, and secure data management

With this flexibility, facilities can unify plant-floor operations, simplify troubleshooting, and future-proof their automation infrastructure.

Download Our Industry Guide

Our product line for the Food & Beverage Industry includes industrial PCs, HMIs and displays that are designed and manufactured for the world’s toughest and most hazardous environments.

Rugged Industrial HMIs at Daisy Data Displays

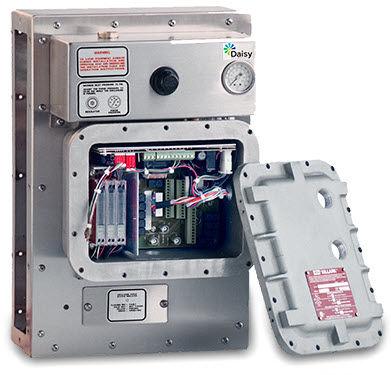

The food & beverage industry relies on a variety of rugged industrial computer systems and equipment to complete operations. To help meet these requirements, Daisy Data Displays offers reliable products for hazardous areas. The engineering and production teams at Daisy Data Displays collaborate to design, build, and test our equipment, including rugged computers, monitors, purge controls, keyboards, workstations, and accessories to optimize their performance and longevity for many applications.

For more details about our equipment and to get started on a solution for your business, contact us today or request a quote for our products.