Industrial HMI’s for Life Science

Pharmaceutical processing systems rely on industrial human interface systems (HMIs) to enhance operator control of complex processes completed by machine and automation equipment. Plant operators and engineers use industrial HMIs to monitor data throughout the production process, and control procedures.

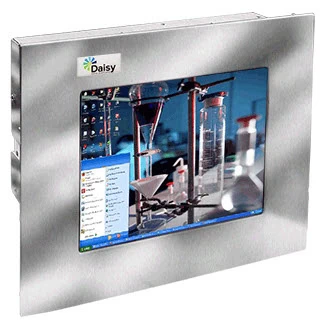

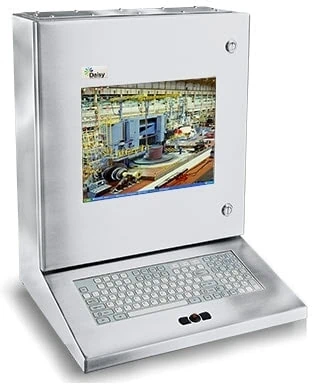

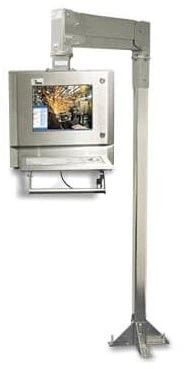

Industrial HMIs feature an IP64 through IP67 rating, indicating that they are engineered to withstand liquid, dust, dirt, debris, bacteria. With a fully-sealed stainless steel enclosure, industrial HMIs are also designed to tolerate the aggressive cleaning procedures in which harsh chemicals/solvents are used to maintain aseptic facilities that are in compliance with strict regulatory practices, good manufacturing practice (GMP) and in some cases, explosion protection directives.

Pharmaceutical facilities place industrial HMIs directly on the production floor. With a glove-friendly touch screen, plant operators have flexible technology that enhances their access to critical data and machine performance, such as batch or dosage control. It allows them to quickly adjust machines should an issue arise.

Built with wi-fi connectivity and/or customized with long-range KVM extenders, off-site production technicians can quickly set-up and troubleshoot industrial HMIs without needing to enter sensitive production areas, such as:

- Batch reactors

- Fermentation

- Retorts

- Centrifuges

- Mix Tanks

- Weighing applications

- Analyzers

- Bulk storage

Life Science Products

Critical features to look for in industrial HMI’s for life sciences applications.

Recommended Products

The following Daisy Data Displays products are frequently used in wide array of Life Science applications. Click learn more to view our available catalog of solutions.

Model 2123AB

2445 Series

2570 Series

2573DB Series

2150AA Series

2670 Series

2620/2520KP Series

2720/2720KB Series

2750/2750KB Series

2610/2510KP Series

2660/2560KP Series

4150AA Series

4320/4520KP Series

4370 Series

4570AB Series

4720/4720KB Series

4750/4750KB Series

4310/4510KP Series

4360/4560KP Series

6800 Series

6900 Series

6950 Series

OEM Series

9040-9050 Series

Model # 9016

Model # 9017

Model # 9123AK

Model # 9167

Model # 9173

Applications of Life Science Products

Industrial HMIs play a crucial role in various aspects of the Life Science industry, contributing to efficiency, safety, exploration, extraction, and overall operations. Here are some key applications where computers are used in the Life Science sector:

Choose the Right Life Science HMI Solution

Well-designed HMIs have become an essential tool for monitoring and controlling highly complex and sensitive operations in modern life science production facilities. At Daisy Data Displays, we work with clients in the life science industry to design and configure HMI systems for various equipment and processes. When you partner with us, you can expect:

- Custom solutions. From glove-friendly touch screens to easy-to-clean stainless steel enclosures, our HMIs can be customized to meet the unique requirements of the life science industry. We have the flexibility to handle large-volume orders for OEMs as well as smaller scale requests for more specialized applications.

- Excellent compliance. To meet the strict safety and quality regulations of the life science industry, we offer HMI units with FM-approved monitors and NEMA 4X & IP66 rated enclosures. For customer convenience, our HMIs and other products can be sorted By Rating and ISO Certification.

- Turnkey integrated solutions. Our turnkey HMI solutions can be provided as standalone units or integrated into a client’s existing system. American-made products. With our American-made solutions, customers can expect excellent quality, fast delivery, and exceptional customer support throughout the production process.

- Lifetime Product Support/Upgrades. We offer lifetime support and regular upgrades for our products, ensuring long-term reliability and performance. This commitment allows customers to keep their systems up-to-date with the latest advancements while maintaining seamless operation over the product’s lifespan.

To learn more about our HMIs and how they can be configured to fit your life science application, please contact us today or request a quote.

Pharmaceuticals

Biotechnology

Medical Devices

Pharmaceuticals

Pharmaceutical focuses on the discovery, development, and commercialization of drugs and therapies to treat various diseases and medical conditions. It includes both small-molecule drugs and biologics, as well as over-the-counter and prescription medications.

Biotechnology

Biotechnology involves using biological processes and organisms to develop products and technologies, particularly in healthcare, agriculture, and industrial applications. This segment is heavily research-driven and includes areas like genetic engineering, gene therapy, and biopharmaceuticals.

Medical Devices

Medical devices encompasses the design, development, and manufacturing of instruments, equipment, implants, and diagnostic devices used in medical procedures and patient care. It covers everything from simple tools like scalpels to complex machines like MRI scanners and advanced diagnostic technologies.

These three segments form the backbone of the life sciences industry, each playing a crucial role in advancing human health, medical research, and the development of innovative healthcare solutions.

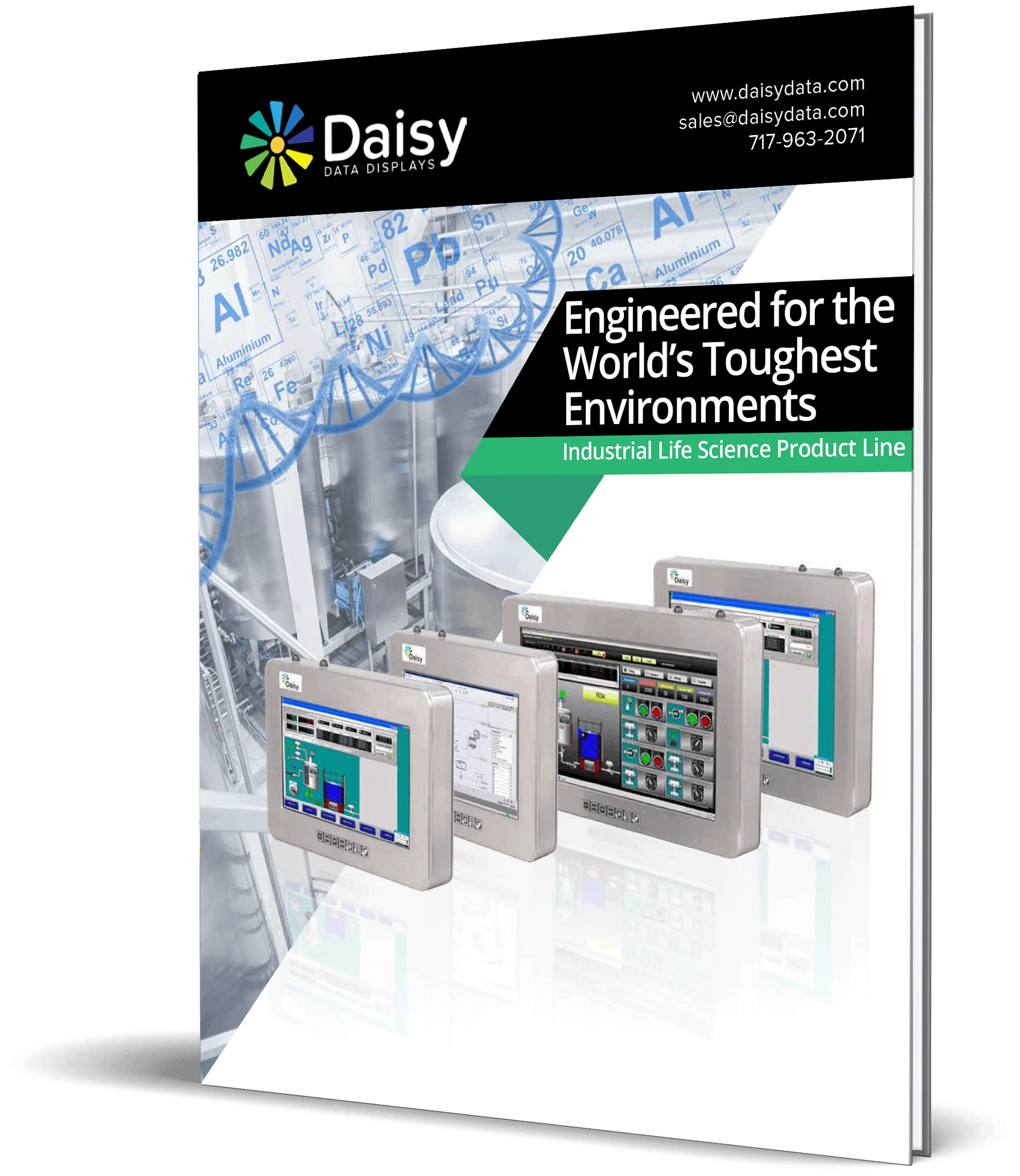

Download Our Industry Guide

Our Life Science product line includes industrial PCs, HMIs and displays that are designed and manufactured for the world’s toughest and most hazardous environments.

Rugged Industrial Computers at Daisy Data Displays

The life science industry relies on a variety of rugged industrial computer systems and equipment to complete operations. To help meet these requirements, Daisy Data Displays offers reliable products for hazardous areas. The engineering and production teams at Daisy Data Displays collaborate to design, build, and test our equipment, including rugged computers, monitors, purge controls, keyboards, workstations, and accessories to optimize their performance and longevity for many applications.

For more details about our equipment and to get started on a solution for your business, contact us today or request a quote for our products.