Rugged Computers for Oil and Gas Exploration

The oil and natural gas (also known as petroleum) industry has a global presence that explores, extracts, refines, transports and distributes petroleum products. The process to successfully extract petroleum for vast uses is broken down into three components: upstream, midstream and downstream. Integrated oil and gas companies have comprehensive operations that combine all three of these sectors.

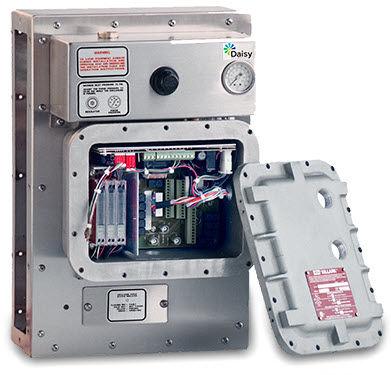

Each of these three areas of the petroleum industry has different uses of hazardous computing technology, from extraction to processing to distribution, that all require fully rugged technology that is tested and approved for hazardous environments.

- Petroleum Exploration and Production -> Upstream

- Petroleum Processing, Storing and Transporting -> Midstream

- Petroleum Refining -> Downstream

The hazardous computing technology used in oil and gas extraction, refining and distribution must be designed to meet and pass rigorous testing to operate in difficult environmental elements, including ultraviolet rays, extreme temperatures, salt water, hose directed water, chemicals, jolts, vibrations and flammable gases.

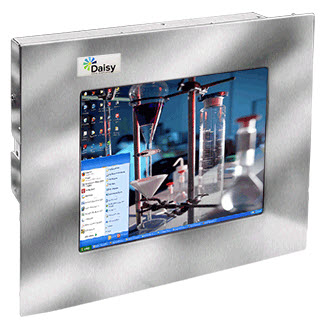

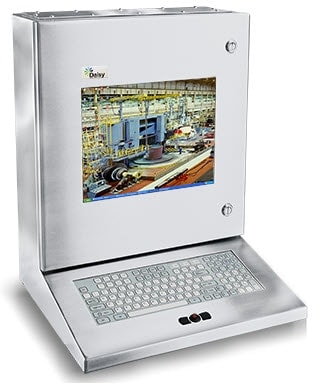

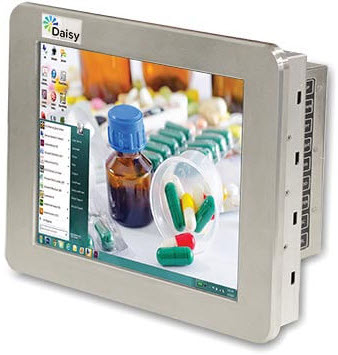

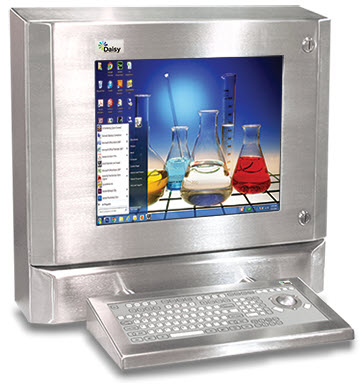

To meet these requirements, Daisy Data Displays manufactures durable and rugged industrial computers and display solutions for the oil and gas industry. As we have 40 years of experience in this industry, we are able to provide some of the most reliable solutions available.

Oil & Natural Gas Products

The listed factors are crucial for computers in the oil and gas industries due to the unique and challenging environment in which these systems operate.

Recommended Products

The following Daisy Data Displays products are frequently used in wide array of Oil and Gas industry applications. Click learn more to view our available catalog of solutions.

Model 2123AB

2445 Series

2570 Series

2573DB Series

2150AA Series

2620/2520KP Series

2720/2720KB Series

2750/2750KB Series

4120 Series

4090 Series

4150AA Series

4320/4520KP Series

4520Cx Series

4570AB Series

4720/4720KB Series

4750/4750KB Series

4820 Series

6800 Series

6900 Series

6950 Series

OEM Series

9040-9050 Series

Model # 9016

Model # 9017

Model # 9123AK

Model # 9167

Model # 9173

Applications of Oil & Gas Products

Rugged HMIs play a crucial role in various aspects of the oil and gas industry, contributing to efficiency, safety, exploration, extraction, and overall operations. Here are some key applications where computers are used in the oil and gas sector:

Rugged Computers for the Oil and Gas Industries

Depending on the application, oil and gas environments can expose computing systems to extreme temperatures, ultraviolet rays, saltwater, chemicals, vibrations, jolts, hose-directed water, and flammable gasses. Because of this, hazardous computing technology used in oil and gas extraction, refining, and distribution must pass thorough testing to function in a variety of environments. Durable mobile computers are critical tools for both natural gas and petroleum operations.

Oil & Gas Applications of Rugged Computers

The extraction of petroleum for vast uses consists of three core components: upstream, midstream, and downstream. Integrated companies in this industry have comprehensive operations that use all three of these combined.

Each area of this industry relies on rugged industrial computers for several uses, including extraction, processing, and distribution. This technology must be tested and approved for a range of hazardous environments.

Upstream

Petroleum Exploration and Production

Midstream

Petroleum Processing, Storing and Transporting

Downstream

Petroleum Refining

Upstream

Petroleum Exploration and Production

The upstream processes in the oil and gas industry entail oil exploration and production, including refining, onshore, petrochemical, and offshore drilling. Specially designed hazardous HMIs streamline upstream operations such as well logging, torque control, downhole operation, measurement-while-drilling (MWD), and directional drilling.

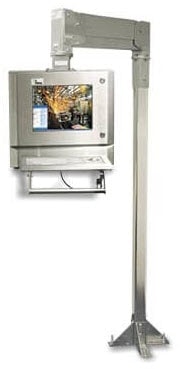

Hazardous computing technology enables engineers and operators to monitor critical performance data and machine control under harsh operating conditions. Because of this, operations normally use easily mounted, compact, and lightweight hazardous computers and monitors that offer added control closer to the drill sites and measurement tools. Easy access to readable real-time performance data allows operators to make key decisions, such as wellbore position, drill bit information, directional data that helps manage the reservoir’s production levels, and the flow of liquid. This in turn allows them to maximize well performance and longevity in the extraction of both conventional and shale oil, which rely on hazardous computing technology.

Midstream

Petroleum Processing, Storing and Transporting

Following extraction through the upstream process, petroleum undergoes processing, storage, and transportation in the midstream sector. Hazardous computing technology is crucial for the midstream cycle, including processes such as distribution, storage, blending, inventory management, and additive injection services. Midstream operations utilize the same rugged computers for monitoring performance and control processing technology for applications such as tanker ships, pipelines, and storage facilities.

For the midstream sector, a common application for fully rugged computers is the monitoring and management of fuel flow in pipelines. With reliable technology that gives easy access to flow metrics and pipeline performance, operators can quickly detect and respond to any critical issues, such as leaks.

Downstream

Petroleum Refining

After both upstream and midstream processes, the refining of petroleum takes place in the downstream sector. Refining processes also rely on rugged industrial computers to protect equipment.