What to Look for in Paint & Coating HMIs and Industrial PCs

Paint and coatings manufacturers rely on precise control and consistent quality throughout their production process. To support this, industrial-grade Human Machine Interface (HMI) systems from Daisy Data Displays deliver cutting-edge technology that helps automate paint production, optimize performance, and reduce time to market.

Our industrial HMIs provide plant operators with enhanced visibility, real-time control, and centralized access to production data—boosting productivity, accuracy, and overall efficiency. From improved lot traceability to more accurate recipe management, HMIs are essential for streamlining every stage of batch production.

Paint & Coating Products

The listed factors are crucial for computers in the paint industries due to the unique and challenging environment in which these systems operate.

Recommended Products

The following Daisy Data Displays products are frequently used in wide array of Paint industry applications. Click learn more to view our available catalog of solutions.

Model 2123AB

2445 Series

2570 Series

2573DB Series

2150AA Series

2620/2520KP Series

2720/2720KB Series

2750/2750KB Series

4120 Series

4090 Series

4150AA Series

4320/4520KP Series

4520Cx Series

4570AB Series

4720/4720KB Series

4750/4750KB Series

4820 Series

6800 Series

6900 Series

6950 Series

OEM Series

9040-9050 Series

Model # 9016

Model # 9017

Model # 9123AK

Model # 9167

Model # 9173

Applications of Paint Products

Rugged HMIs play a crucial role in various aspects of the paint industry, contributing to efficiency, safety, exploration, extraction, and overall operations. Here are some key applications where computers are used in paint facilities:

Designed for Demanding Industrial Environments

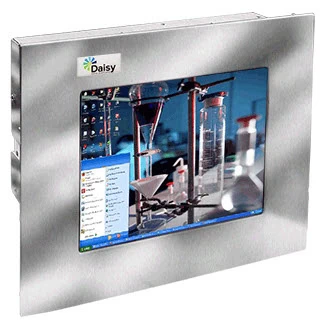

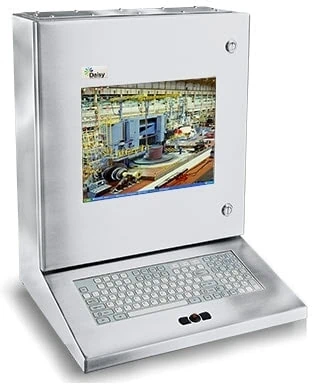

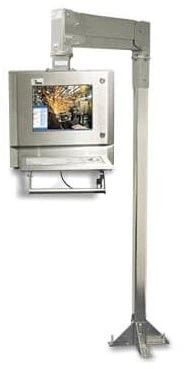

Engineered for durability, Daisy’s industrial computers and displays are built to thrive in the harsh conditions of paint manufacturing facilities. Our systems are sealed to meet NEMA 4X and IP66 standards, protecting against dust, dirt, water, and chemical ingress. Their rugged construction resists corrosion and contamination, ensuring continued operation with minimal maintenance, even in environments with heavy use of solvents and industrial cleaning procedures.

High-brightness LCD displays, with optional PCAP or PCT touchscreen technology, allow operators to view and interact with production dashboards right on the plant floor. Whether monitoring process variables or adjusting batch settings, users can expect seamless performance and long-term reliability.

Depending on the application, oil and gas environments can expose computing systems to extreme temperatures, ultraviolet rays, saltwater, chemicals, vibrations, jolts, hose-directed water, and flammable gasses. Because of this, hazardous computing technology used in oil and gas extraction, refining, and distribution must pass thorough testing to function in a variety of environments. Durable mobile computers are critical tools for both natural gas and petroleum operations.

Formulation and Processing

Packaging & Filling Operations

Warehousing

Safe for Hazardous Areas

Paint manufacturing environments often involve the handling of flammable liquids, combustible dust, and volatile organic compounds (VOCs)—conditions that can create hazardous locations. Daisy Data Displays offers Class I, Division 2 and ATEX/IECEx compliant solutions designed specifically for these challenging settings.

Our hazardous-area certified HMIs and industrial PCs are intrinsically safe, explosion-resistant, and rigorously tested to operate safely in areas where ignitable gases or vapors may be present. With Daisy’s technology, you can maintain worker safety while meeting strict regulatory standards—without sacrificing performance or productivity.

Download Our Industry Guide

Our industrial paint product line includes ruggedized PCs, HMIs and displays that are designed and manufactured for the world’s toughest and most hazardous environments.

Rugged Industrial Computers at Daisy Data Displays

The oil and gas industry relies on a variety of rugged industrial computer systems and equipment to complete operations. To help meet these requirements, Daisy Data Displays offers reliable products for hazardous areas. The engineering and production teams at Daisy Data Displays collaborate to design, build, and test our equipment, including rugged computers, monitors, purge controls, keyboards, workstations, and accessories to optimize their performance and longevity for many applications.

For more details about our equipment and to get started on a solution for your business, contact us today or request a quote for our products.