How Rugged Computers Are Used in Process Automation

Process automation is becoming increasingly popular today across many industrial sectors. The three main goals of this automation technology include automating certain processes, centralizing information, and minimizing the need for human input.

Industrial computers are integral to successful process automation. Daisy Data Displays manufactures durable, reliable industrial computers and displays. Highly specialized and regulated industries depend on us to supply them with standard and custom solutions for harsh environments. Learn more about how rugged computers are utilized in process automation.

What Is the Role a Typical Computer in Automation?

High-volume manufacturing processes are difficult for humans to perform with the necessary efficiency, which is why many of these processes use automated computer systems. Computers facilitate precise and efficient manufacturing to boost the output of complex products.

Rugged computers are specifically intended for use in harsh or potentially hazardous environments.

The Relationship Between Rugged Computers and Process Automation

Over the years, rugged computers have helped shape the future of automation, while developments in automation have led to innovations in rugged computing systems. They have a symbiotic relationship.

Unlike other types of computing systems, rugged computers are intended for 24/7, around-the-clock operation without being affected by the dust, vibration, and extreme temperatures of manufacturing environments. Most rugged computers must be rated at least to NEMA 4X, IP67, and other standards.

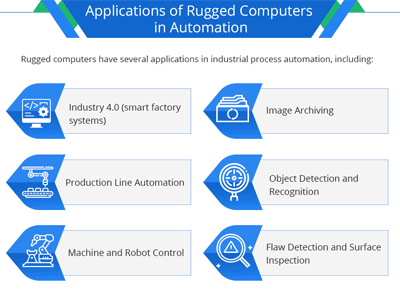

Applications of Rugged Computers in Automation

Rugged computers have several applications in industrial process automation, including:

- Industry 4.0 (smart factory systems)

- Image archiving

- Production line automation

- Object detection and recognition

- Machine and robot control

- Flaw detection and surface inspection

Examples of Automation Software

The following are examples of popular automation software used in process automation applications:

Emerson

Emerson’s software enables more eco-friendly, secure, and safer manufacturing processes. The DeltaV™ Distributed Control System (DCS) is a user-friendly automation system that helps simplify operations and reduce project risk. The suite of products and services included in DeltaV™ are designed to optimize plant performance through the integration of easy-to-use, intelligent controls.

Designed for water and power applications, Emerson’s Ovation™ DCS provides generator excitation control, vibration monitoring, scalable footprints, safety instrumented systems (SIS), and embedded simulation capabilities.

Wonderware/AVEVA

Wonderware, now rebranded as AVEVA, is a leading provider of human-machine interface (HMI) solutions. The AVEVA® System Platform includes multiple features for industrial process automation, including data connectivity, deployment, configuration, security, communication, and more.

The software’s object-based approach enables more capabilities, including the ability to optimize system sustainability, establish new data source connections, and improve reporting. Its powerful templates make it easy to quickly add critical functionality to any system. Users can also build and test different types of application objects prior to incorporating them into production.

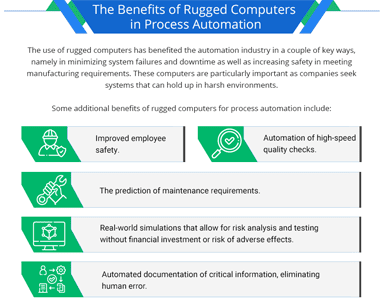

The Benefits of Rugged Computers in Process Automation

The use of rugged computers has benefited the automation industry in a couple of key ways, namely in minimizing system failures and downtime as well as increasing safety in meeting manufacturing requirements. These computers are particularly important as companies seek systems that can hold up in harsh environments.

Some additional benefits of rugged computers for process automation include:

- Improved employee safety

- Automation of high-speed quality checks

- The prediction of maintenance requirements

- Real-world simulations that allow for risk analysis and testing without financial investment or risk of adverse effects

- Automated documentation of critical information, eliminating human error

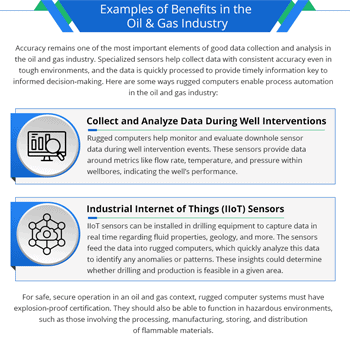

Examples of Benefits in the Oil & Gas Industry

Accuracy remains one of the most important elements of good data collection and analysis in the oil and gas industry. Specialized sensors help collect data with consistent accuracy even in tough environments, and the data is quickly processed to provide timely information key to informed decision-making. Here are some ways rugged computers enable process automation in the oil and gas industry:

- Collect and analyze data during well interventions: Rugged computers help monitor and evaluate downhole sensor data during well intervention events. These sensors provide data around metrics like flow rate, temperature, and pressure within wellbores, indicating the well’s performance.

- Industrial Internet of Things (IIoT) sensors: IIoT sensors can be installed in drilling equipment to capture data in real time regarding fluid properties, geology, and more. The sensors feed the data into rugged computers, which quickly analyze this data to identify any anomalies or patterns. These insights could determine whether drilling and production is feasible in a given area.

For safe, secure operation in an oil and gas context, rugged computer systems must have explosion-proof certification. They should also be able to function in hazardous environments, such as those involving the processing, manufacturing, storing, and distribution of flammable materials.

Examples of Benefits in the Life Sciences Industry

Life science and pharmaceutical processing facilities also benefit from rugged computers, which improve operator control of various process automation equipment. Industrial HMIs must be rated to IP64/65/66 standards, verifying that they can withstand dirt, dust, debris, liquid, and bacteria. To maintain the strict hygiene and sanitation requirements of this industry, many of these rugged computers must also tolerate multiple rounds of aggressive cleaning processes often using harsh chemicals.

Located on the production floor, pharmaceutical rugged computers have antibacterial membrane keyboards and high-definition, glove-friendly touch screens, giving onsite operators easier access to key data and allowing them to make process changes as needed. Equipped with wifi, rugged computers can be customized with long-range KVM extenders so that offsite technicians can set up or troubleshoot the computers without physically entering sensitive production areas.

Specific applications for rugged computers in the life sciences/pharmaceutical industry include:

- Analyzers

- Batch reactors

- Bulk storage

- Centrifuges

- Fermentation

- Mix tanks

- Weighing applications

Rugged Computer Solutions from Daisy Data Displays

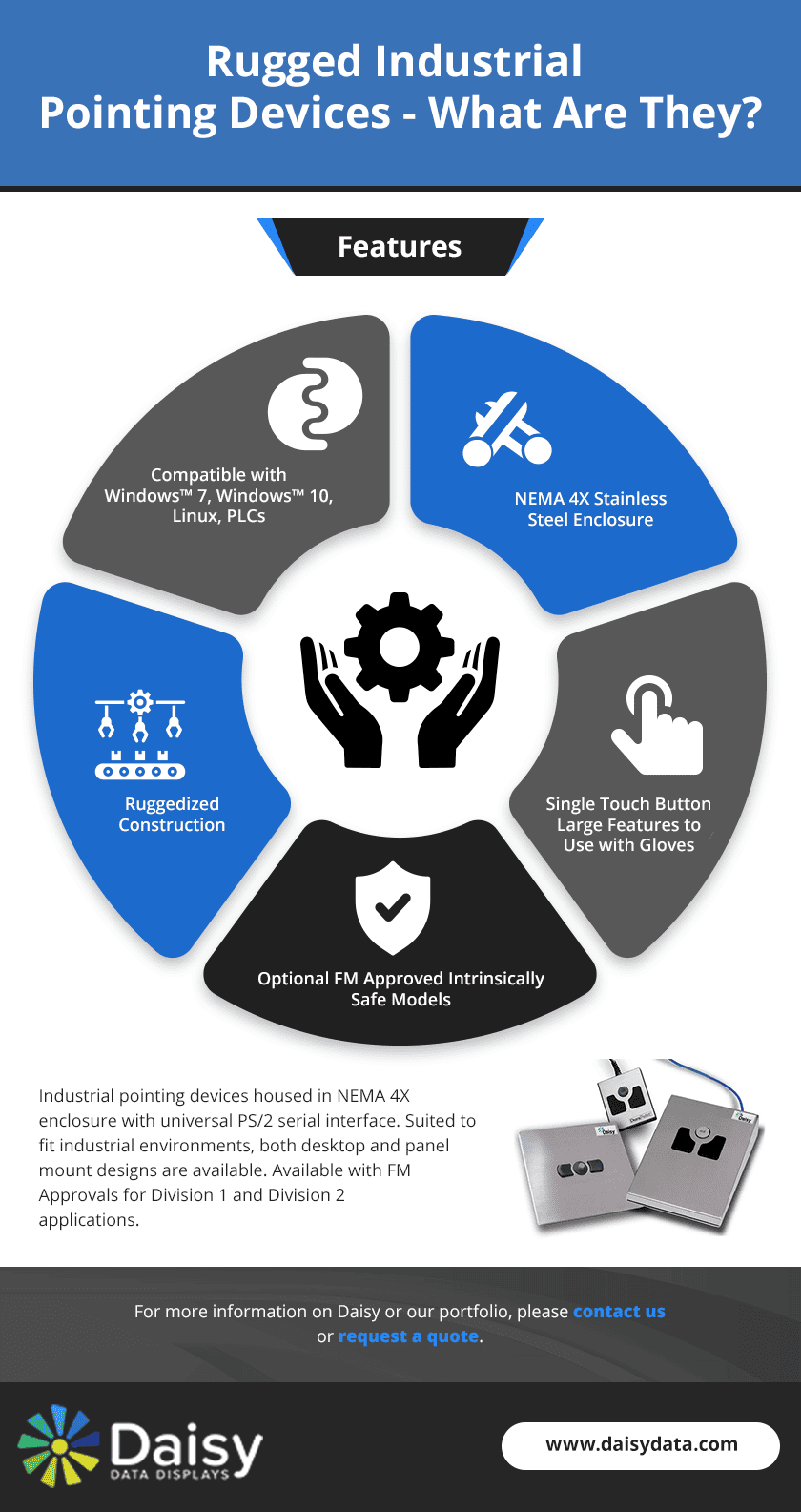

Using rugged computer systems can facilitate reliable process automation in many industries, such as oil and gas. At Daisy Data Displays, we design, build, and test our rugged industrial computer systems and accessories so that they can work in a variety of harsh environments. Daisy Data Displays is an ISO 9001:2015 registered manufacturer, and our 100% American-made products are NEMA 1, NEMA 4, NEMA 4X rated, and meet Class I, II and III, Division 2, Group A-D, and F&G standards.

Contact us to learn more about our capabilities, or request a quote to find the right product for your operations.